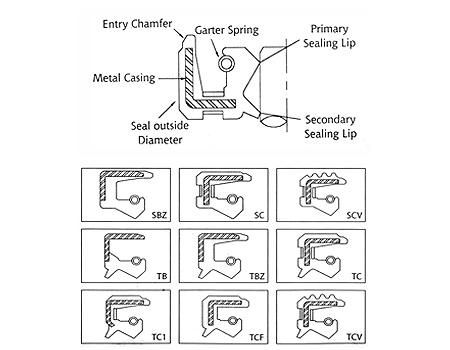

Oil Seals

An Oil seal is a combination of metal shell and elastomer vulcanized together to the designed dimensions having a sealing lip. These lip-type seals are used for retaining fluid or grease in equipment employing rotating shafts. In some instances, the shaft is stationary and the housing rotates. Sealing of a lip-type seal with low differential pressure is normally a result of a designed interference fit between the shaft and the flexible sealing element, which is usually fitted with a garter spring. An interference fit between the outside surface of the seal and the housing bore surface retains the seal in the housing and prevents leakage at the outer diameter.

More than one hundred standard seal profiles have been discovered. Few of the popular standard profiles are given to suit the majority of the application. Varieties of metal to-polymer combinations are also available based on application media, temperature, weather conditions, shaft speed, and pressure.

The most commonly used polymer in oil seals is nitrile and other polymers like Silicon, FKM, Polyacrylic, EPDM, and Neoprene can be supplied on request.

- Metal Part – Mild Steel – IS 513/1079

- Polymer – Nitrile Rubber

- Spring – Zinc Coated Garter spri